We Care to Mettle

by Jeremy Skorupa

When considering what approach to take to the medical market, Scherdel Medtec looked at the medical field as an encompassing entity. Looking at the methods used by medical professionals in general, provided a good example of how things are done and how Scherdel fits into the industry.

The people of Scherdel create an environment of compassion. This flows through the group as commitment to the people at the company’s core. It’s important for us to know that we’re doing something meaningful and that lives are positively impacted by what we do. Management realizes that we can’t connect with everyone on a personal level, but that doesn’t stop us from being aware of our impact on those individual lives. In the beginning we really didn’t know how to apply this concept to what we were doing. This challenge is particularly difficult to address when making metal components in a manufacturing environment.

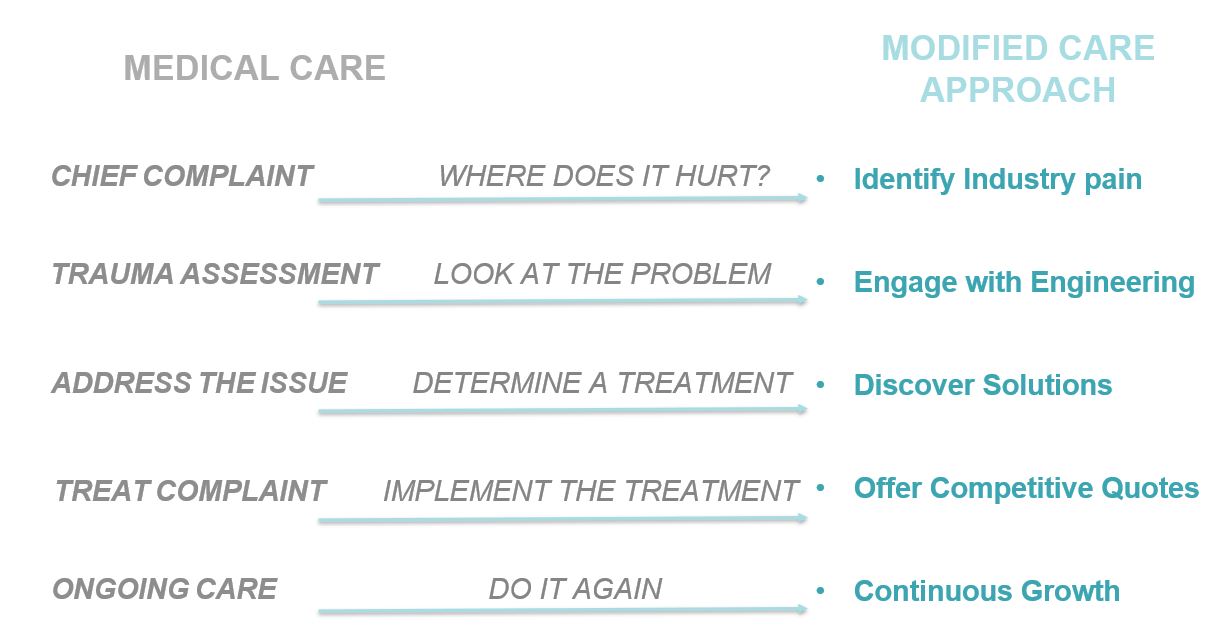

By studying and developing an understanding of medical professionals methods regarding a patient is where we truly discovered our path to the market as well as how we’d like to approach it. The initial contact a professional has with a patient is not indifferent from how we approach the market. The first interaction a medical professional has is often an assessment of some kind. In this, a patient would be asked a series of questions to assess their condition. It’s likely that every person has some level of experience with this when they see a family doctor. Simple questions like “where does it hurt?” and what seems to be the problem?”. Medically this is called the patient’s “chief complaint”.

Once the problem is identified the next step is to look at it and see if there’s anything that can be done immediately. This ability to look at problems objectively is at the core of our approach to manufacturing as well.

The medical professional will often address the issue and determine a treatment. In this step we would draw on our experience and expertise the same as any professional in any field of study would do. Incorporating engineering and in special cases even doing testing to determine the best approach to reaching a solution.

The next step is to implement the treatment. A doctor or other medical professional might suggest a treatment or prescription. Then continue with ongoing care.

This is also the same as our approach. We offer a solution that fits the needs of the individual customer just as if they were our patient and we were “caring” for them.

Ongoing care is the part in all the movies where the doctor says, “call me in a week”.

For us this step is simply to continue through the process of design, prototype, simulation and production again and again. We understand that as our customers grow, we too will grow.

This mutually beneficial interaction is what drives our desire to make sure that Scherdel Medtec is the leading manufacturer of complex bending & stamping parts, springs and wire forms for drug delivery devices.

Scherdel offers a different perspective on sales and engineering.