INTRODUCTION to SCHERDEL MEDTEC SIMULATION SERVICES

by Drew Jelgerhauis

Development Engineers are constantly trying to understand how their design will perform under various conditions, environments, and applications. Their Project Managers are trying to reduce the timeline to get to market sooner and cut costs to beat the competition. Simulation services are a great tool to ‘test‘ and evaluate designs and thus improve time to market and reduce overall cost before even making a prototype.

Scherdel Medtec mettles in simulation in a big way.

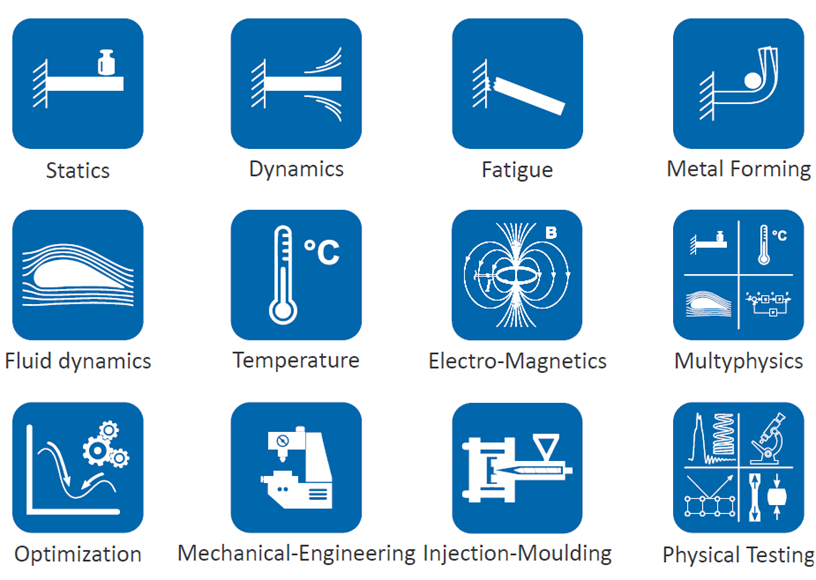

Scherdel Medtec is committed to providing the best engineering for your medical device components. Our simulation services include statics/dynamics, fatigue, metal forming, fluid dynamics, temperature, electro-magnetics, multiphysics, optimization, mechanical engineering, and injection molding. In addition to these simulation services we supplement this analysis with a wide range of physical testing.

Our simulation team performs hundreds of simulation projects every year and the amount of these numerical simulation tasks continues to grow year over year as the value of the results continues to improve with the continual advancement in software, algorithms and engineering knowledge. Over the past five years we have increased the number of simulation projects over 30% annually. This is in part due to the significant value that it provides but also in the growing types of simulations we can perform.

Let’s take a simple compression spring as an example. We can simulate the wire drawing process to determine the stress levels throughout the wire before we even begin to form it into a spring. Controlling the variables from the first process can help determine and improve the performance after the final process. As we progress into the coiling process we can then determine and optimize the process for best results based on the specifications of the given spring. The next process may involve annealing which we can simulate in our temperature simulation. Another process often used in the manufacture of springs is shot peening. Our manufacturing simulation can provide analysis of the process to optimize for distribution and wear reduction in this process

Some of the benefits that result from numerical simulation are:

- Deviation between simulation and testing is less than 10%

- First time right prototypes are reality

- Simulation speeds up development times

- Simulation finds better solutions

- Simulation is always faster than trial and error with prototypes

- Simulation gives more insight

- Simulation costs are investigations in fault prevention

- Coordinated use of simulation and testing is the fastest way to new products

Please mettle in our simulation capabilities at our Siment homepage: www.siment.de (yes it is in German but you can learn more about our capabilities and maybe some useful German terms too!)

This blog that is dedicated to drug delivery device metal components, has been titled Mettle as a play on words. The word mettle derived originally from the word we use for metal. Mettle is defined now as a person’s ability to respond well to difficulties. Scherdel Medtec works with global customers on developing metal components in their devices that overcome difficulties in drug delivery. This market serves billions of people the world over making their lives healthier, safer, and alleviating pain and life-threatening conditions. Mettle is our platform to communicate solutions and insights to overcoming difficulties in the drug delivery market. We will share global trends and insights as well as our own teams’ technical expertise.

We aim to respond and help our customers overcome difficulties in the development and manufacturing of their drug delivery devices. Scherdel has over 130 years of deep expertise and broad experience in the design and manufacturing of springs and metal components. You might say we have mettle in metal!